We have 30 years of experience in hammer blade manufacturing and our customers are located all over the world. We firmly believe that our unique technological innovations and inventions will make our products your best choice.

Products have been provided to more than 50 countries and regions around the world

Get a Quote4 Unique Advantages

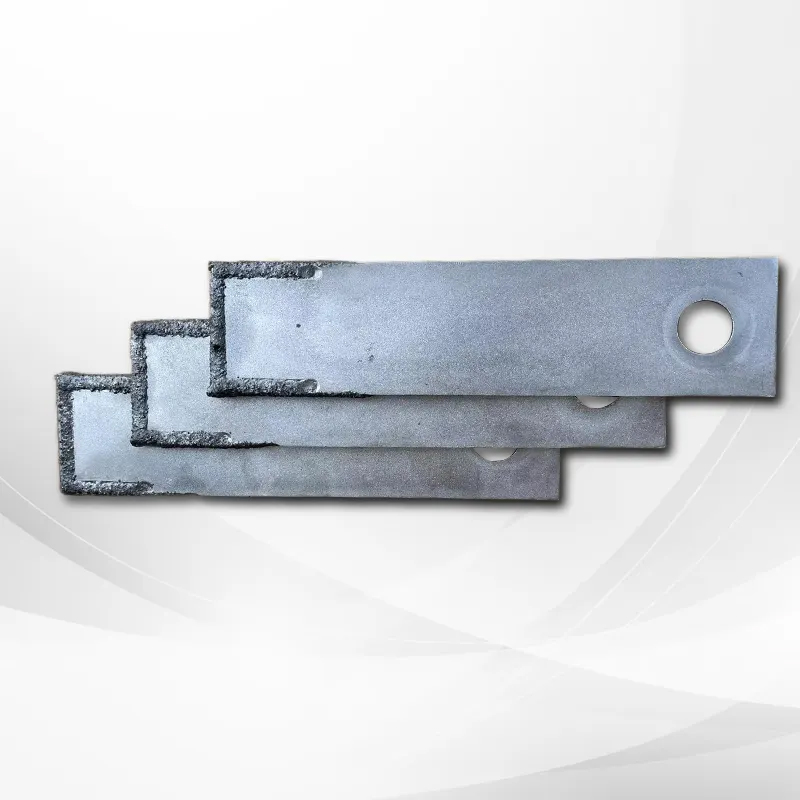

Super wear-resistant

Super wear-resistant

HMT tungsten carbide wear-resistant hammer blade. The service life is 3-4 times longer than other similar products, reducing the time for replacing hammer blades and saving costs.

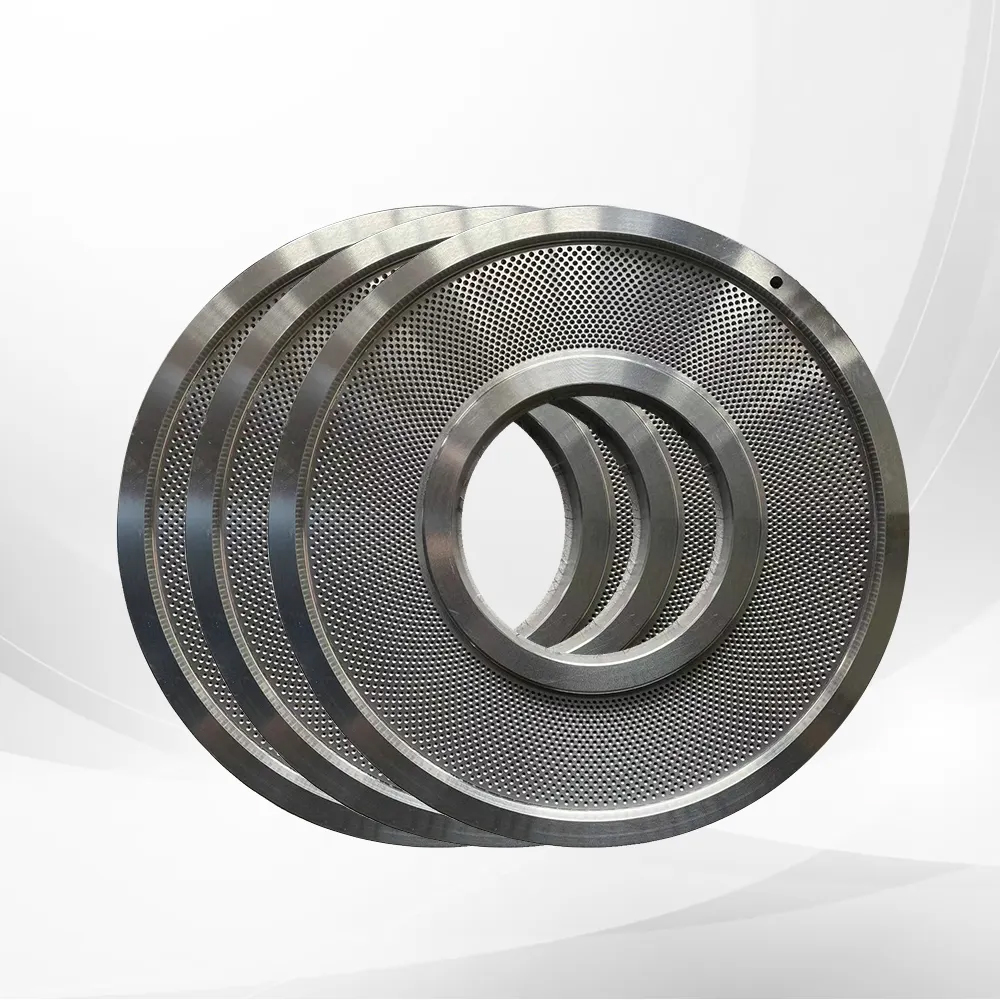

High crushing efficiency

High crushing efficiency

HMT tungsten carbide hammer blades form two sharp corners as their top wear layer wears, boosting crushing efficiency, output and saving electricity. Others wear to a circular arc, reducing efficiency and increasing power use

The wear-resistant layer does not fall of

The wear-resistant layer does not fall of

HMT tungsten carbide wear-resistant hammer blade. The service life is 3-4 times longer than other similar products, reducing the time for replacing hammer blades and saving costs.

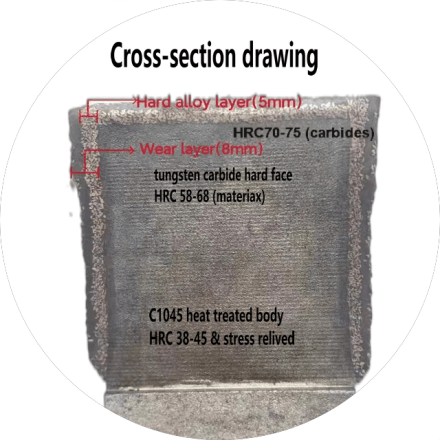

The body of hammer blade does not break

The body of hammer blade does not break

We can control the hardness of the substrate to be between 38-42 HRC, but the wear-resistant layer of the hammer head is between 60-62 HRC, and the hard alloy layer is between 72-75 HRC. Hammer heads have high hardness and wear

Here you can view the latest exhibition news of the company and the latest information of the company

01

After a year of long waiting, our company's application for registration of the "HMT" ···

Discover More01

Dear customers and partners:Thank you very much for your continuous support to HMT Machinery!HMT Mac···

Discover More

After a year of long waiting, our company's application for registration of the "HMT" ···